Atkinson petrol engines save more fuel

If you are looking for a new car/bike, you will probably have a huge checklist to select the right car. The most important and common attribute would be fuel efficiency.

This is more popular in India. The popularity of the phrase ‘Kitna deti hai’ proves it.

Therefore, companies are looking for alternatives. Using the Atkinson cycle instead of Otto cycle seems to be an excellent choice.

Table of Contents

Contents

1. Working of a petrol engine

2. Turning moment diagram

3. Implementation of Atkinson cycle in petrol engines

4. Explanation using thermodynamic cycles

5. A problem

6. Few mentions

7. One misconception

8. Final taughts

Working of a petrol engine

Before getting to the point, let me explain how a petrol engine works.

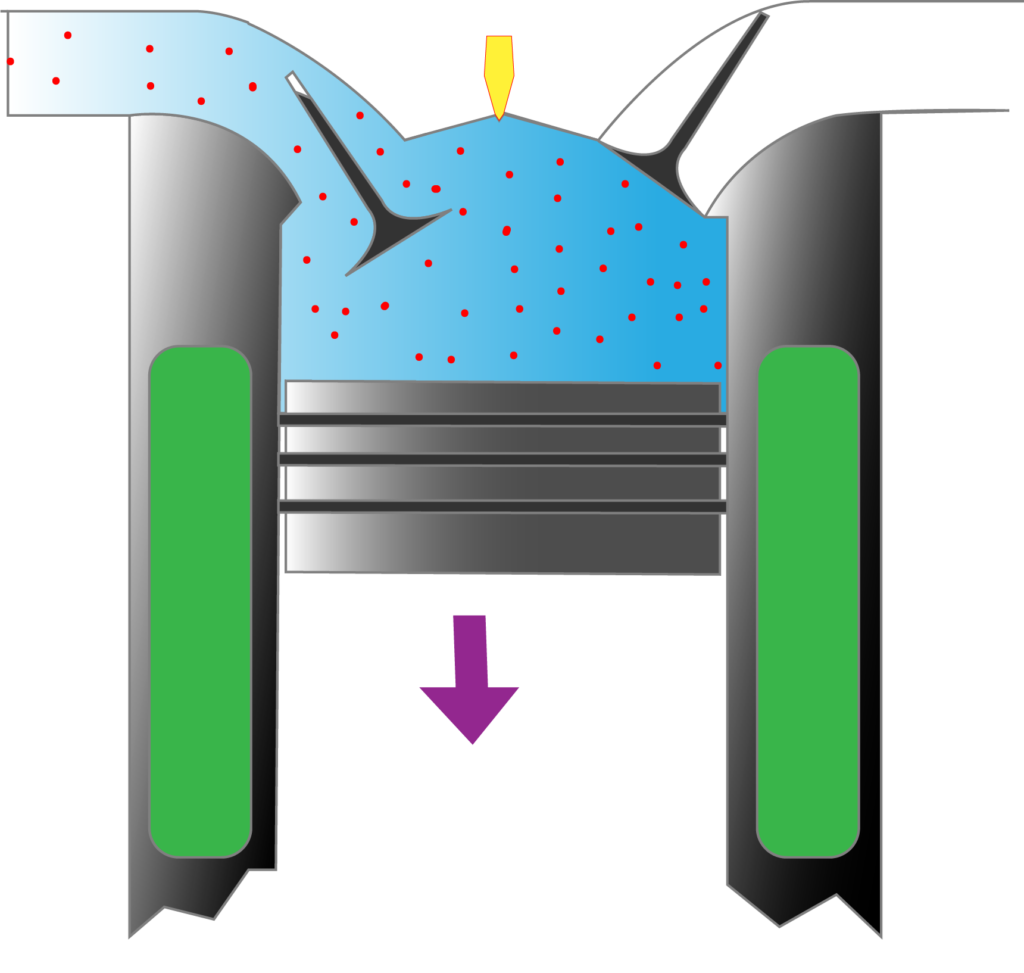

An internal combustion engine has 4 strokes;

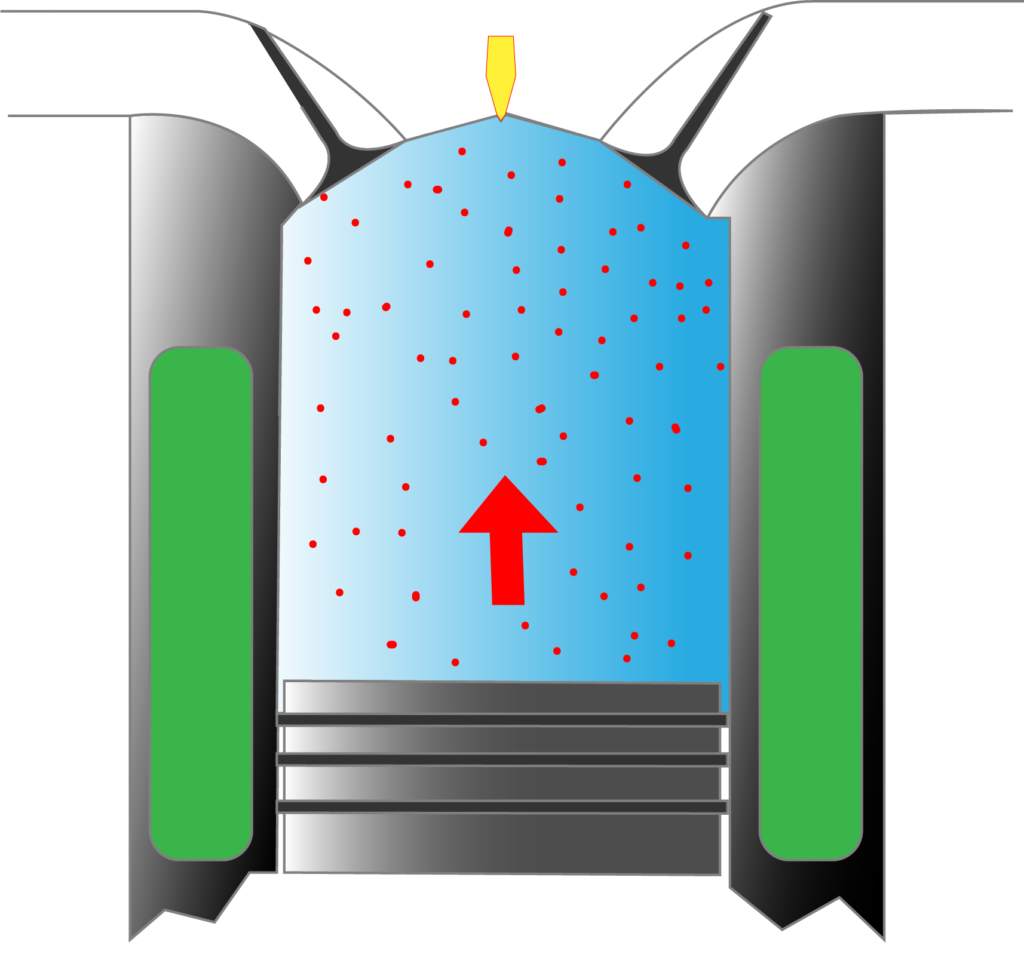

1. Intake – The intake valves open and air-fuel mixture comes in

2. Compression – The intake charge is compressed

Now the spark plug ignites the intake charge.

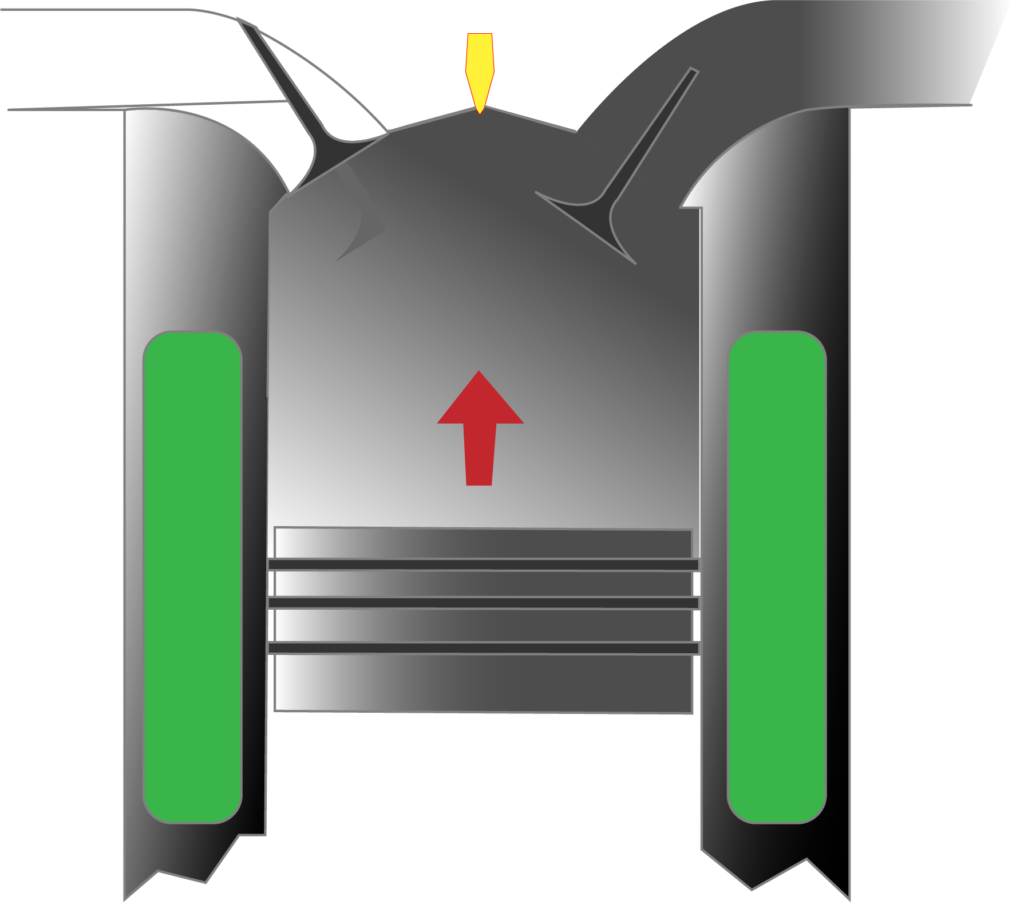

3. Expansion/Power – Enormous force (because of the combustion) pushes the piston down.

4. Exhaust – The exhaust valve opens, sending the exhaust gases out of the combustion chamber.

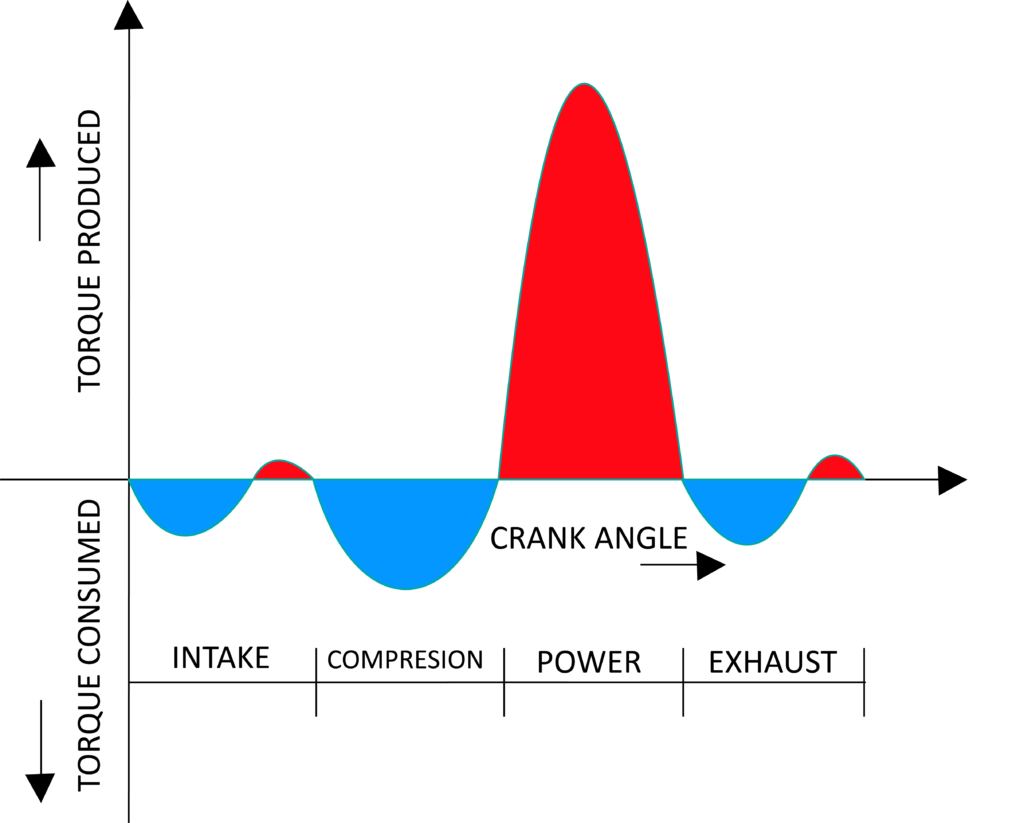

Turning moment diagram

Let me introduce you to this.

This is a turning moment diagram of a single-cylinder engine. This gives us an idea of how much torque an engine produces in its expansion stroke. And how much it consumes in other strokes.

Yes, the engine consumes a part of the torque it produces in order to keep the other strokes running.

A flywheel comes for the rescue.

A flywheel is connected to the crankshaft of the engine. This stores the energy from the expansion stroke due to moment of inertia and serves them during other strokes.

Implementation of Atkinson cycle in Petrol engines

Implementation of Atkinson cycle is simple.

The key idea is to decrease the pumping loss. That is the loss due to powering the other strokes (here compression stroke).

If we could reduce the length of compression stroke for the same power stroke, we can save a significant amount of fuel.

But how is it done?

A simple valve timing is a solution. If I hold the intake valve open even after intake stroke, some amount of charge goes out as the piston moves up. This reduces the length of the compression stroke. Hence some amount of energy required to compress the intake charge reduces.

This means that the engine is consuming less fuel.

Explanation using thermodynamic cycles

Take a look at the Atkinson and Otto cycle (the traditional spark ignition engine cycle).

Both these cycles have three processes in common.

- Isentropic compression (2-3) – compression stroke

- Constant volume heat addition (3-4) – Fuel ignition stage

- Isentropic expansion (4-5) – Power/Expansion stroke

Apart from this, these two strokes follow constant pressure process

- Intake (1-2)

- Exhaust (6-7)

These are not a part of the cycle and I have plotted constant pressure (yellow) lines below the cycle.

The only difference is the heat rejection stroke (5-6 in Otto and 6-6′ in Atkinson) and Intake (1-2-2′). Otto follows constant volume and Atkinson follows constant pressure.

Though both the cycles follow the same intake process, there is a significant difference. The valve opens similarly for both the cases i.e. till TDC (1-2). But the valve is open in Atkinson petrol engines for a longer duration. Which means the intake process still continues till 2′. This means that the compression ratio reduces, as I explained previously.

The cylinder pressure after expansion stroke is higher in the Otto cycle. This is due to a higher compression ratio and more fuel burnt. Therefore, as soon as the exhaust valve is open gases escape (before piston moves up) making it a constant volume heat rejection process.

But such is not the case in Atkinson petrol engines. And the exhaust gas goes out as the piston pushes them out, making it constant pressure process.

But there is a problem

The following is the T-S (Temperature Vs Entropy) plot for the same cycles.

It is clear from the plot that Otto cycle occupies a larger area. The area under a thermodynamic cycle denotes the amount of work done per cycle.

This means that Atkinson petrol engines produce less power than the traditional engines.

In other words, Atkinson cycle petrol engines burns lesser fuel than traditional engines. Leading to lesser power produced.

Few mentions

Almost all the hybrid vehicles in the market use the Atkinson cycle. Since the electric motor support during high torque requirements, it proves to be the ideal choice.

Also, by changing the valve timing, one can shift between the cycles. This is how many non-hybrid vehicles like that of Toyota use.

Hyundai uses Atkinson cycle for their hybrids and some non hybrid vehicles.

Many mid-sized Earth dreams engines from honda use Atkinson cycle.

Kia also uses these petrol engines in some of its cars. For instance, the Kia Seltos (2.0 version).

A common misconception

A lot of you might have this doubt. How decreasing the compression ratio increases the efficiency?

This is a fair question. As higher compression leads to higher cylinder temperature leading to better combustion, hence efficiency.

This question becomes correct when we consider the same engine input parameters. That is two identical engines running with the same load, speed, amount of air-fuel mixture and different compression ratio. Then, the engine running at a higher compression ratio would work efficiently.

But the amount of fuel burnt in Atkinson petrol engines is lesser. Then the above statement is not applicable in these engines.

Finally

Atkinson cycle petrol engines are known for its fuel efficiencies. We can achieve it using simple modifications with the valve timing. Also, the ability to shift between Atkinson and Otto cycles makes it an amazing choice.