COVID-19 has caused a lot of troubles to the automotive industry. It still is creating a fuss in India and almost every industry has taken a big hit except healthcare. Thanks to work from home, the IT sector is doing comparably well. Now, this does not mean that these sectors do not have any issues. But I am not here to speak about these sectors, so let me jump in.

It is definitely a roller coaster for the auto sector where the industry had no demand and then had an enormous demand. Finally the second wave happened. Demand or no demand, this industry definitely struggled to compete with such an extreme scenario.

Table of Contents

The Timeline – COVID-19 and Automotive Industry

I am pretty sure that no one would forget what happened in March 2020. The prime minister announced a nationwide lockdown. This is something that none of us would have even imagined. Then came April 2020, a month that carved a scar in the auto sales chart.

April 2020 set a record on the sales chart, a month with no sales, and this was harsh. Though all the other industries were affected, the BS6 implication had created a headache among the automakers and dealers. There were dealers who offered enormous discounts on their stocks to clear them as soon as they can. Some went even further and registered the vehicles and sold them in the used car market. Of course, many of them might have filed huge losses.

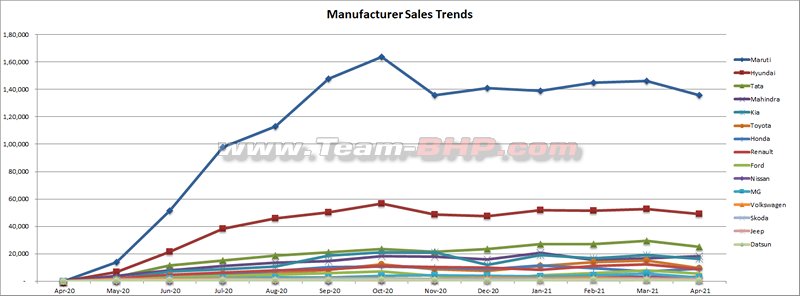

May 2020 was an interesting month as even one car sold would have a tremendous impact on the month on month attribute. Obviously, every manufacturer filed a whopping hundred percent rise MOM in sales. I found it unique.

Demand Increases – COVID-19 and Automotive Industry

Soon, there was an uphill in demand. This was mostly because of the fears COVID-19 had induced among the people. People became more aware of the issue and did not want to take any risk. One who would use a bus to reach his place of work considered a two-wheeler. And the one who uses a 2 wheeler considered buying a car. In simple words, people wanted their own vehicle to commute to their offices.

Soon dealership started facing a surge in buyers. Many dealers have not expected this to happen as there was a decline in the sales since 2019. Even the manufacturers had their own issues other than incorrect estimation- the semiconductor shortage. I will come on this later in this blog.

My Experience – COVID-19 and Automotive Industry

Yes, even I had an experience buying a car during this time for my grandparents. I told them we need to wait for a couple of months for December to get some good offers. And yes there were some decent offers during this month. But this was no way close to the 2019 one, as sellers and manufacturers were cautious on the BS6 impact. Lessons learnt from the previous incident :D.

Less discount was the least of my issue as people buy cars like samosas. I contacted several dealers and got one response.

The offer is still there. But we have no car left in stock.

Finally, we found just 2 cars, a Santro and a celerio. The Santro was sold in just a couple of hours. Therefore, we rushed to the nearest Maruti Suzuki Arena to book it. Woah!!! another strange experience for me. After this, not just Ertiga, but the entire portfolio had massive waiting periods.

It thrilled the Dalal Street as well auto stocks like Tata Motors, Motherson Sumi, etc had a huge rally. These companies posted fantastic Q3 21 results as well. Though Tata posted a great Q4, the management comment was a bit cautious indicating Q1 22 could be tricky.

The Scrappage Policy

The government had announced a scrappage policy which has a good potential for automakers to sell more vehicles. This is not really a short term goodie and its effect can be felt in the long run. Does it solve the purpose of climate change? More on this in a future blog.

Semiconductor Shortage – The nightmare for the automotive industry

The biggest blocker this industry is facing is the acute semiconductor shortage. The semiconductor issue is now the most debated topic of economists when discussing the auto industry.

A car or any other vehicle needs hundreds of semiconductor chips. This includes the heart and soul systems like the ECU, ABS, crash detection systems, instrument cluster, locking and others th keep th ca running.

On the other hand, a car needs chips for its infotainment systems, Blind spot assist, Park assist, Navigation systems, ADAS, Connected car tech and diagnostics and much more. And with the current level of shortages, the automakers are taking a terrible blow. This has also affected other industries like home appliances and industrial equipment as well.

Many automakers announced frequent halts in production to tackle this situation, leading to more waiting periods and extensive losses. Layoffs are becoming more common, especially among the small auto ancillaries. Others, however, are chipping off unwanted features that need these chips like blind spot assist, etc. They are into producing the base variants more as it would require lesser semiconductors.

What is causing it?

According to NewScientist, the shortage is because of both demand and supply side.

Again, incorrect prediction of sales by automakers because of the roller coaster demand led to this issue. Companies halted or reduced production during the pandemic. Also, they had placed lesser orders for these semiconductors. This marked the beginning of the issue.

This made the semiconductor makers concentrate less on the auto industry. The work from home model increased the demand for laptops, headsets, smartphones, etc. So they shifted their concentration to the tech sector.

On the supply side, there are multiple issues. Taiwan, being one of the biggest suppliers, had to reduce its production as the country is facing drought. And this industry requires a lot of water to produce these chips. A fire accident in one of the semiconductor maker in japan and the closure of factories in texas because of terrible weather worsened the case.

The second wave in India – COVID-19 and Automotive Industry

The second wave is disastrous, and the country is in crisis. Announcements of new lockdowns created more issue for this sector. The country is facing a shortage of beds, oxygen and medicines. This means people would postpone their idea of buying a new car. On the other side, many industries are into supplying oxygen as a part of their national duty.

Lower Margins!

This did not end here. If you watch the news, you would be very much aware of the global surge in commodity prices. Commodities like steel and copper have reached decade-high prices. Steel is one of the most important factors affecting the margins of a vehicle. To make the case worse, there seems to be a shortage of iron ore. This means the companies have to increase the prices of the car or live with lower profit margins.

Steel Price chart since last year.

Courtesy: Tradingeconomics.com

BS6 has already made automakers to increase the prices and now steels and semiconductors could make the case even worse.

When will thing get back to normal?

That is a billion-dollar question. While the semiconductor issue might last for at least a couple of months. But COVID-19 is something that is in our hands.

Wear a mask, Maintain social distancing and most importantly get vaccinated as soon as you can