Flexi fuel vehicles may be unfamiliar to many of us but are very popular in American countries. As the name suggests, Flexi fuel vehicles can run on different fuels. Ethanol is one such alternative fuel that is present in many starch-based crops. Since we get it from plants, we call it biofuels.

Not just Ethanol, we can make biofuels from pretty much everything that has hydrocarbons. From plastics, and tyres to plant and animal wastes. We use pyrolysis, a thermal decomposition process to convert them to usable fuels. -More on pyrolysis in the future.

Coming back to ethanol, Flexi fuel vehicles could run on 100 percent ethanol or in blends with petrol say 50 percent ethanol and 50 percent gasoline. Sugarcane and corn are pivotal sources of Ethanol. And we have a lot of sugarcane with us in this country. – more on production later.

Table of Contents

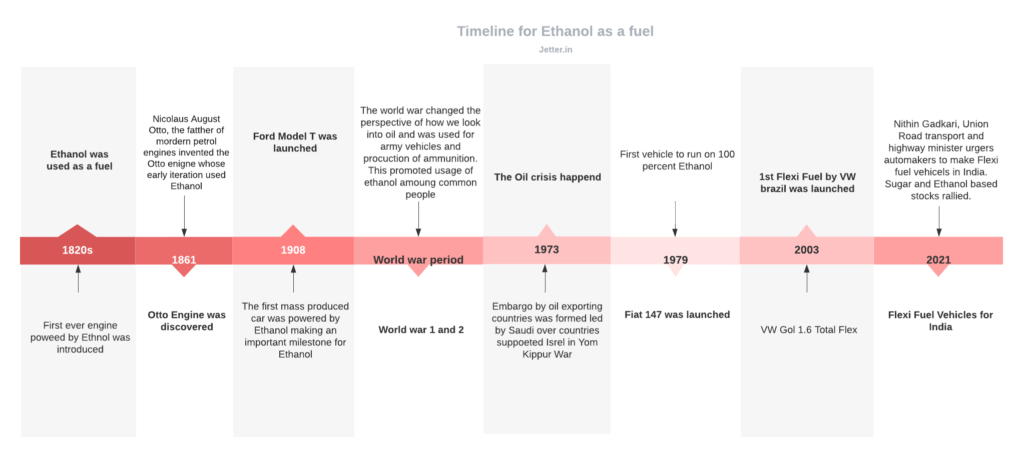

Flexi Fuel Vehicles – History

Phase 1

We started using ethanol as a fuel centuries ago, around the 1820s to be more specific. I could connect some dots here. Both Ethanol and Electricity were deployed in the transportation industry in the past. And now we are back to square one but with advanced iterations obviously. Guess life is a circle!

Moving on! Nikolaus August Otto, the person whom we can attribute as the father of modern Petrol engines used ethanol in one of the early iterations of his Otto engine. I am pretty sure that no mechanical/Auto engineer might say I don’t know this man. You may like this article on Atkinson cycle engines – Click here to know more.

Ford Model T, a benchmark for not just the auto industry but also for the ‘industry’ as a whole was powered by ethanol. This makes the first mass-produced car to be the first mass-produced ethanol car as well. Henry Ford made this car run on ethanol due to world war 1. Speaking of which, it made humans understand the need for oil and its importance. Oil was in great demand during this period. Tanks, Aircraft, Ships, All-terrain vehicles and other army vehicles needed lots of fuel. Also, they need oil for making ammunition. This impacted the domestic usage of fossil oils and people started using ethanol.

Phase 2

Let me call the developments till world war 2 phase one for ethanol in the auto sector. Phase 2 is where things get more interesting. 1973 is a very important year in the 20th century. This was the period that changed how people travel. This was the time the infamous oil crisis happened. The USA was one of the worse affected countries. Queues were stretching several miles at the gas stations as there was less supply. The country is known for gas-guzzling cars. Skyrocketing oil prices coupled with low supply impacted the industry very badly. This was the time when the native automakers lost their market share to their Asian counterparts like Toyota which made affordable, economical and small cars. Let us understand what really happened.

Yom Kippur war AKA the Ramadan war is the reason behind the crisis. It was fought between the Israelites and the Arab collation in October 1973. The reason for the war is beyond the scope of this article. But the problem started when the USA joined the war alongside Israel. This agitated the Arabian countries and they formed an embargo led by Saudi against the countries that supported Isreal in the war. This meant the United States would face an acute shortage of oil shattering their economy.

Post Oil crisis

Everyone understood the impact oil dependence has on a country’s economy. This is so true as the trucking, aviation and shipping industries will be hit and this would freeze the entire supply chain. This is a disaster. Therefore, countries like Brazil and the USA started looking for alternatives.

Brazil is one of the biggest producers and exporters of sugarcane, a major source of ethanol. They wanted to use this to come out of the oil dependence. The Brazilian government invested heavily in sugarcane to ethanol infrastructure. Urged the companies to make cars that can run on ethanol completely.

Fiat answered this with the 147, the first production car to run on 100 percent ethanol. Soon many vehicles started rolling out making Brazil a country that uses ethanol completely. But this industry suffered a lot when the crude prices fell making petrol more affordable than ethanol. VW Brazil came up with the Golf 1.6 Total Flex in 2003. This was the first Flexi fuel vehicle that was put to production.

Recently, Union road transport and highway minister Nithin Gadkari called for automakers to make Flexi fuel vehicles in India. And sugar stocks in India rose after this announcement.

Flexi Fuel Vehicles – Production of Ethanol

Let us see how to make ethanol. As I already mentioned, industries make ethanol from starch-based crops. Fermentation is the name of the process.

This process involves grinding sugarcane or corn, and mix it with water and some enzymes. Then cook it using a steamer. This process enables the enzymes to break the starch down. Further, add glucoamylase and which converts starch into sugar. Then add yeast to this.

The yeast converts the sugar to ethanol and CO2. Find below the simplified chemical reaction.

(C6H10O5)n (Starch) + nH2O -> nC6H12O6 -(Yeast)-> 2nC2H5OH

Flexi Fuel Engines – Working

There is not much difference between a normal petrol engine and the engine in Flexi fuel vehicles. In fact both works on the same thermodynamic principle. But the only difference lies with the Engine Control Unit (ECU) that changes the Air Fuel Ratio (AFR).

Before I say much about the tuning, let us analyse ethanol. Ethanol has a calorific value of about 30 MJ/Kg which is less compared to petrol (~43 MJ/Kg). This means ethanol does not give out as much energy as petrol for the same mass. So is its energy density (energy per volume). This is the reason why ethanol engines give lesser mileage. But on the bright side, ethanol has an octane rating of 110 which means variable compression engines can run on higher ratios improving thermal efficiency.

Therefore, we need to pump in more fuel in order to compensate for the energy requirement. Ideally, gasoline needs an AFR of 14.7:1 i.e. 14.7 parts of air for every part of fuel. Accounting for the lower energy content, ethanol engines need a stoichiometric AFR of around 9:1.

This is the key factor for Flexi fuel vehicles. All we need is a sensor to detect the fuel blend ratio and communicate it to the ECU. This system needs a variable-pressure fuel pump that can increase or lower the flow depending on the fuel you put in. The system is simplified as below.

Here, the sensor detects the blend ratio and signals to the ECU. The ECU commands the fuel pump and injectors with altered flow rates and hence the AFR will change as per the need.

Ethanol is a bad fuel when it comes to ignition in cold weather conditions hence some Flexi fuel vehicles have an auxiliary petrol tank near the engine that it uses during those circumstances. Some automakers just add a glow plug just like a diesel engine to tackle this case.

Blend Sensor

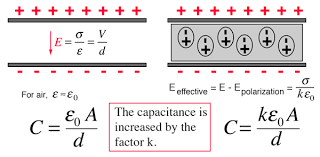

There is nothing in this system that I should be explaining as I have discussed previously. Hence let me explain the blend sensor. This is essentially a capacitor with an AC supply. The ECU calculates the blend ratio with the change in capacitance. Let me dig deeper.

Hope you know what a capacitor does. – it holds the charge. It will charge until the voltage between its plates equals the supply voltage. Now let me a dielectric medium between the plate. This dielectric material will form a dipole upon charging (sometimes dipoles exist naturally). The dipoles will arrange themselves in a direction opposing the charges of the plates.

This means that the overall voltage between the plates goes down. As I said above, the capacitor will be charged further. Now the capacitor can hold more charge than before. Capacitance is the ability of a capacitor to hold a charge. Hence the addition of dielectric material increases the capacitance here.

C = eA/D

Here C is the capacitance, e is permittivity (depends on the dielectric), A and D are the Area of the plates and the distance between them respectively.

Ethanol compared to petrol can increase the capacitance hence ECU can sense the blend ratio accurately in real time. You can put petrol or ethanol wherever and whenever you want and this system can handle it. But how does it sense?

The answer is frequency. The input for this sensor is AC voltage and frequency will decrease with an increase in capacitance. The following plot can give you a fair idea.

One possible explanation for this behaviour can be, as the frequency increases, the dipoles have a hard time aligning. Simply higher frequency leads to lower polarisation. This means, our capacitance will be reduced. The blend sensor uses this phenomenon in the opposite sense.

Flexi Fuel Vehicles – Pros and Cons

Pros

- Eco-friendly – It is a carbon-neutral technology, as we do not drill the fuel from the earth. The carbon footprint of these vehicles will be compensated by the replantation of crops/trees.

- Even the production of ethanol does not harm the environment much especially when we compare it with hydrogen and other fossil fuel production.

- Can obtain ethanol from a variety of sources.

- Lower crude dependency

- Farmers are benefitted and now they can a bang for their buck

- This will develop new industries creating more jobs and a better economy.

Cons

- The ethanol-based economy can disrupt the food chain. If crops fail and ethanol is still produced due to a lack of proper guidelines, it can cause lots of issues.

- The lower calorific value of ethanol translates to lower fuel economy. The range of the vehicle goes down.

- If crude price crashes, there is no point in using ethanol and hence the entire industry will be affected.

- We still lack proper infrastructure for production and distribution. Also, it is a new domain for automakers in India.

Ethanol fuel cells

Just like hydrogen fuel cells, ethanol can also be used in fuel cells. This is more efficient than IC engines and is safer to transport than hydrogen. More about ethanol fuel cells later. The reason we don’t use them is that platinum-based catalyst which is very expensive. Also, there is not much research on this technology. Partly because ethanol is used as fuel for IC engines. To know more about fuel cells, Check this out.

| Anode |  oxidation |

|---|---|

| Cathode |  reduction |

| Overall reaction |  redox reaction |

2023 Update

The government of India has recently announced that E20 blends will soon be available in selected fuel pumps from April 2023. The government has also announced a deadline of 2025 for a nationwide adaption of E20 blends. This may marginally impact your fuel economy but on the bright side, there is a potential reduction in fuel prices that can be expected.

Also, this reduces the dependency India has on oil imports thereby reducing the trade deficit which is really good for the economy.

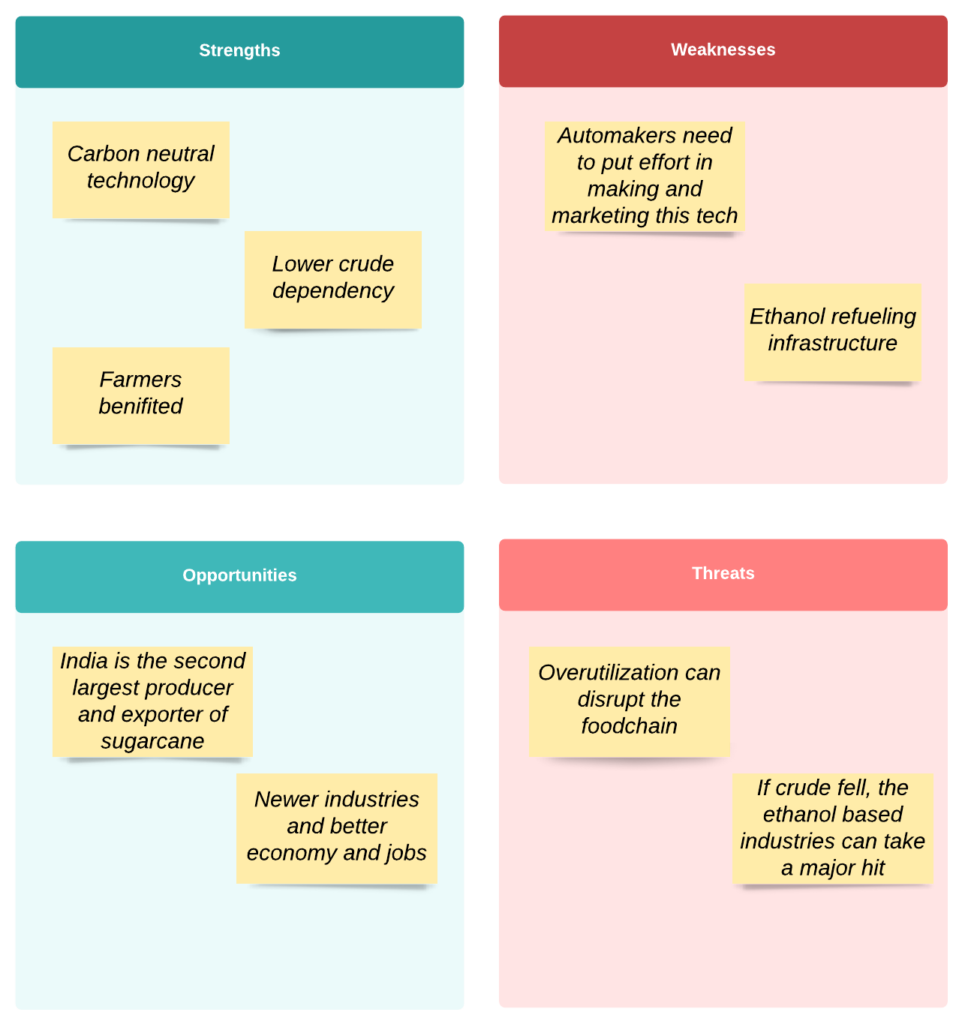

Flexi Fuel Vehicles – The SWOT Analysis